What is Anthracite Filter Media?

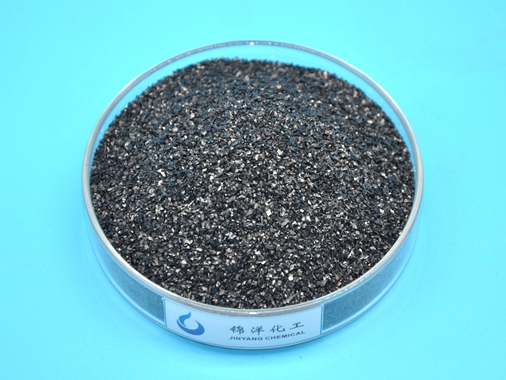

Anthracite is a high-grade form of coal that has a high carbon content and low volatile matter. When used as a filter media, it is usually crushed into small grains or pellets. Its primary use in water filtration is due to its physical and chemical properties which make it an effective medium for removing impurities from water.

Characteristics of Anthracite Filter Media:

1. High Carbon Content: Anthracite has a high carbon content, which provides excellent adsorption properties, capturing a wide range of contaminants.

2. Low Ash Content: The low ash content of anthracite reduces the potential for clogging and increases the lifespan of the filter media.

3. Hardness and Durability: Anthracite is hard and durable, making it resistant to physical wear and chemical degradation, which helps in maintaining its filtering efficiency over time.

4. Effective Filtration: It has a high specific gravity and a porous structure, allowing it to trap particles effectively and provide high filtration performance.

Applications:

1. Water Treatment: Anthracite is commonly used in municipal and industrial water treatment plants. It is often employed in multi-media filter systems, where it serves as a primary or secondary layer to filter out suspended solids and particulates.

2. Wastewater Treatment: It can also be used in the treatment of wastewater, including in systems designed to remove organic materials and other contaminants.

3. Filtration Systems: Anthracite is used in various filtration systems, including those for swimming pools, aquariums, and other settings where water quality is crucial.

Advantages:

1. High Filtration Efficiency: Due to its granular size and porous nature, anthracite provides high filtration efficiency, capturing fine particles that other media might miss.

2. Extended Filter Life: Its durability and resistance to clogging extend the operational life of the filter, reducing maintenance and replacement costs.

3. Cost-Effective: Anthracite is generally cost-effective compared to some other filter media, offering a good balance between performance and price.

Considerations:

1. Initial Cost: While anthracite is cost-effective in the long term, the initial setup might be higher compared to some other filter media.

2. Maintenance: Regular backwashing is required to clean the media and maintain its efficiency, which is a common requirement for most filtration systems.

In summary, anthracite filter media is valued for its high filtration efficiency, durability, and cost-effectiveness, making it a popular choice in various water treatment applications.

Anthracite filter media is widely used in various filtration applications due to its high filtration efficiency and durability. Here are some of the primary application areas:

1. Municipal Water Treatment

Drinking Water Filtration: Anthracite is used in water treatment plants to filter out suspended solids and particulate matter from raw water sources. It often serves as a key component in multi-media filtration systems, where it works alongside sand and garnet to improve water clarity and quality.

2. Industrial Water Treatment

Process Water: In industrial settings, anthracite filters process water used in manufacturing and production processes. It helps remove impurities that could affect product quality or damage equipment.

Cooling Water: Used in cooling systems to remove particulates from water before it is reused or discharged, ensuring efficient and safe operation of cooling equipment.

3. Wastewater Treatment

Secondary and Tertiary Treatment: Anthracite is employed in the secondary and tertiary stages of wastewater treatment to remove fine particulates and organic matter. This helps improve the quality of treated effluent before it is released or further processed.

Sludge Dewatering: In some cases, anthracite can be used to filter and dewater sludge generated during the treatment process.

4. Swimming Pool Filtration

Residential and Commercial Pools: Anthracite is used in swimming pool filtration systems to maintain clear and clean water. It effectively traps debris, leaves, and other contaminants, ensuring that pool water remains safe and aesthetically pleasing.

5. Aquarium Filtration

Freshwater and Marine Aquariums: In aquariums, anthracite helps maintain water clarity by removing suspended particles and impurities, contributing to a healthier environment for aquatic life.

6. Mining and Mineral Processing

Water Recovery: Used in mining operations to filter water used in mineral processing and to recover water from tailings. It helps in managing water quality and recycling.

7. Food and Beverage Industry

Process Water: In food and beverage production, anthracite is used to filter process water, ensuring that contaminants do not affect the quality and safety of the final products.

8. Chemical and Pharmaceutical Industry

Chemical Processing: Filters process water and removes impurities that could interfere with chemical reactions or the quality of pharmaceutical products.

9. Oil and Gas Industry

Produced Water Treatment: Anthracite is used to treat water that is extracted along with oil and gas during production, helping to remove suspended solids before the water is discharged or reused.

10. Environmental Remediation

Contaminated Site Remediation: Used in systems designed to treat and clean contaminated water at polluted sites, such as landfills or industrial spills.

11. Fire Protection Systems

Fire Sprinkler Systems: In some fire protection systems, anthracite is used to filter water to ensure that it is free from particulates that could clog sprinkler heads or damage the system.

Summary

Anthracite filter media is versatile and effective across various sectors, including municipal and industrial water treatment, wastewater treatment, swimming pool and aquarium maintenance, and more. Its high filtration efficiency, durability, and ability to handle diverse contaminants make it a valuable tool in maintaining water quality and operational efficiency in many applications.

Using anthracite filter media effectively involves several key steps, including selecting the right type, configuring the filtration system, and maintaining it properly. Here’s a step-by-step guide on how to use anthracite filter media:

1. Selecting the Right Anthracite Media

Determine Application Needs: Identify the specific requirements of your filtration system, including the type of water (drinking, industrial, wastewater), desired filtration level, and flow rate.

Choose Granulation Size: Select the appropriate granulation size for your application. Coarser media is suitable for larger particles and higher flow rates, while finer media is better for capturing smaller particles.

Check Quality: Ensure the anthracite has the required carbon content, porosity, and bulk density for effective filtration.

2. Configuring the Filtration System

Single-Media Filtration:

Installation: Load the anthracite media into the filter vessel, ensuring an even distribution.

Operating Conditions: Set up the system to allow water to flow through the media bed under gravity or pressure, depending on the filter design.

Multi-Media Filtration:

Layering: Place the anthracite layer on top of other media like sand and garnet in a filter bed. The typical arrangement is anthracite on top, followed by finer media below.

Flow Configuration: Configure the system to allow water to pass through the different layers sequentially.

Dual-Media Filtration:

Setup: Install the anthracite as the top layer and sand as the bottom layer.

Operation: Ensure water flows from the anthracite layer through the sand layer for optimal filtration performance.

Pressure Filters:

Loading: Place anthracite media inside a pressurized filter vessel.

Pressure Management: Operate the system under the recommended pressure conditions for effective filtration.

Gravity Filters:

Setup: Position the anthracite media in a gravity-fed filter unit.

Flow Control: Allow water to flow through the media by gravity, ensuring a consistent and controlled filtration process.

3. Operating the Filtration System

Start-Up: Gradually introduce water into the filter system to avoid disturbing the anthracite media. Ensure proper wetting and settling of the media.

Flow Rate Management: Adjust the flow rate according to the media’s specifications and the desired filtration performance.

Monitoring: Regularly check the system for performance issues, such as reduced flow rate or increased pressure drop.

4. Maintaining the Filter System

Backwashing:

Frequency: Schedule regular backwashing to clean the anthracite media and remove accumulated particles. The frequency depends on factors like water quality and filter usage.

Procedure: Reverse the flow of water through the media bed to dislodge and flush out contaminants. Follow the manufacturer’s guidelines for backwashing duration and water flow rate.

Replacement:

Assessment: Periodically inspect the anthracite media for signs of wear, clogging, or degradation.

Replacement: Replace the media when its performance deteriorates beyond acceptable limits or as recommended by the manufacturer.

Cleaning:

Pre-Treatment: Use appropriate cleaning agents or methods if the media becomes fouled by substances that can’t be removed by backwashing alone.

5. Disposal and Replacement

Safe Disposal: Follow local regulations for the disposal of used anthracite media, especially if it has been exposed to hazardous substances.

Replenishment: Obtain new anthracite media from a reputable supplier and follow proper procedures for its installation.

Summary

Using anthracite filter media involves selecting the appropriate type and size, configuring it correctly within the filtration system, and maintaining it through regular backwashing and inspections. By following these steps, you can ensure efficient and effective filtration performance, whether for municipal water treatment, industrial applications, or other uses.