(1).jpg)

(1).jpg)

(1).jpg)

(1).jpg)

1. White PAC:

Pure, refined PAC with minimal impurities, commonly used for drinking water treatment and food applications.

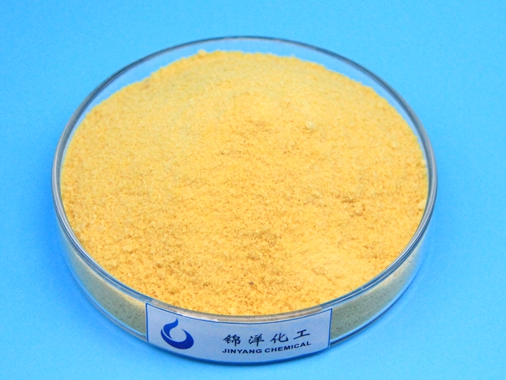

2. Yellow PAC:

Slightly colored due to higher basicity or impurities, often used in wastewater treatment and industrial applications.

3. Brown PAC:

Indicates a higher level of impurities or organic matter, typically used in specific industrial processes.

These color classifications can influence the choice of PAC for particular applications, as they may indicate different properties and levels of effectiveness.

Poly Aluminium Chloride (PAC) can be classified by appearance into the following categories:

1. Liquid PAC:

Typically clear to slightly yellowish liquid.

Easy to handle and mix, commonly used in water treatment processes.

2. Powdered PAC:

Fine, white to off-white powder.

Requires dissolution in water before use, suitable for specific applications.

3. Granular PAC:

Coarse granules, often off-white or yellowish.

Offers easier handling and storage, used in various industrial applications.

1. Dilution: PAC is usually supplied in liquid or powdered form. If using powdered PAC, it needs to be dissolved in water to form a working solution. The concentration of the solution depends on the application and water quality parameters.

2. Mixing: Stir the PAC solution thoroughly to ensure uniform distribution and dissolution. This step is crucial to activate the coagulation properties of PAC.

3. Dosage: Determine the appropriate dosage of PAC based on the characteristics of the water to be treated. Factors such as pH, turbidity, and the concentration of contaminants influence the dosage. It is typically measured in milligrams per liter (mg/L) or parts per million (ppm).

4. Applicatio: PAC is added to the water either directly or through a dosing system. It is important to ensure that PAC is evenly dispersed throughout the water to maximize contact with contaminants.

5. Mixing and Reaction: After application, allow sufficient time for PAC to mix and react with the impurities in the water. This allows for effective coagulation and formation of flocs.

6. Settling or Filtration: Once the flocs are formed, they settle to the bottom of the treatment tank or are removed through filtration processes. The clarified water can then proceed to further treatment or discharge.

7. Monitoring: Regularly monitor the treatment process to adjust PAC dosage as needed based on water quality parameters and treatment goals.

By following these steps, PAC can effectively treat water by coagulating suspended particles and contaminants, leading to clearer and cleaner water suitable for various industrial, municipal, and environmental applications. Always refer to the specific instructions and recommendations provided by the PAC manufacturer for optimal results.